News

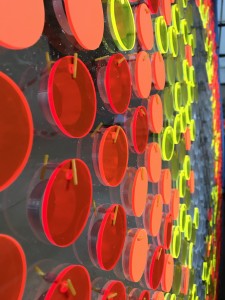

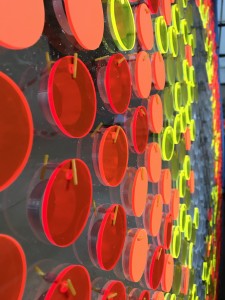

Midnight Sun is a large, flame-coloured disc that rises over Sydney harbour near Farm Cove. The 15mm thick clear acrylic disc measures 2m in diameter and has almost 1700 holes laser cut to accept small clear, yellow, orange and red discs, which create its golden shimmer.In the morning it is lit by the rays of the sun, and at night hundreds of tiny coloured discs are illuminated by a LED and flutter and shimmer in the breeze.

Midnight Moon appears to float magically above the Royal Botanic Garden. It serves as a beacon for this section of the Light Walk, drawing visitors through the Queen Elizabeth II Gate from the Sydney Opera House forecourt and along the paths of the Garden.

Created the same as the sun but this time with muted pastel mini-discs of grey, blue and green, the design reflects the shadows, undulations and craters of the moon’s surface, rather than being a purely abstract representation.

#westonwilliamson

Christmas Tree Camden Market.

The brief was to manufacture a Camden Market Christmas Tree which depicted the 12 days of Christmas.

The Camden Market Christmas Tree is 3.3 meters tall 1.5 meters wide and weighs close to 120kg, there are 12 faces each with a different graphic giving a contemporary take to the 12 days of Christmas.

The structure of the Camden Market Christmas Tree is manufactured from 18mm thick exterior grade plywood and clad in acrylic mirror, our in house graphics team then manufactured and applied the various images from a frosted vinyl.

The idea is for visitors to take a “selfie” in front of their chosen day of Christmas

The job was designed, manufactured and installed in 7 days

The creation was designed and installed by Phill Creates Studio and can be seen for the next 6 weeks in Camden Market.

Illuminated Raging Bull sign installed at The London Designer Outlet in Wembley.

Manufactured from a CNC routed ACM tray with 20mm thick laser cut letters faced off with black acrylic pushed through, the gold edge detail on the black lettering is cut from a gold metallic vinyl. When lit the letters have a “halo” effect.

Our second 3000 x 2000 CNC router is now installed. Along with our 3 laser cutters this now gives us massive capacity for machined panels.

The CNC routers specialize in cutting Polycarbonate (Makrolon, Lexan) PETG, PVC, ABS, Foamex and Aluminium Composite (such as Dibond Alu-panel and Reynobond) whilst the laser cutters focus predominantly on Acrylic (Perspex, Plexiglas etc)

If you have any CNC routing requirements please give us a call.

Holloway Plastics have been chosen to manufacture and install the advertising hoardings at Lichfield Rugby Club. These are ACM panels mounted into an aluminium frame and fitted between the concrete pillars.

We recently donated a batch of material to the RSA Academy Tipton for use in their resistive materials class. Here is a selection of items that the students have made. We think they look pretty good.

This Jaguar XJ13 was a prototype racing car developed by Jaguar to challenge at Le Mans in the mid 1960s.

It never raced, and only one was produced. The car has not been officially valued, but a £7 million bid for it was declined by the owners in 1996.

The car is undergoing a full restoration at present and we have manufactured the acrylic engine cover and side screens.

…

The youtube link to the first engine start up is here.

https://youtu.be/kNyWVyUcr4Q

We have recently completed a project manufacturing a series of built up letters and logo’s for a local Sign and Digital company.

Manufactured from 5mm thick Perspex the letter fronts were laser cut, the returns moulded by hand and the mounting panels CNC routed from 10mm thick PVC Foam. Everything was then bonded together with Tensol and cured.

One of the many branding blocks manufactured for John Lewis Birmingham.

1 of 7 oversize acrylic covers manufactured for Harvey Nichols to celebrate London Fashion Week. These were nearly eight foot tall and three feet wide and designed to have removable panels so that the model could be changed easily. We also had to get them manufactured within a week!

Hello, this our first blog on our brand new web presence, which we feel will showcases our experience, capabilities and expertise.

We have some great stories to tell about wonderful projects we have had the privilege to work on, unique problems we have been able to solve, which, when not ‘top secret’ we will share with you. We have continued to invest in new state of the art forming, cutting and finishing equipment; we have innovated ways of working, pioneered and mastered new plastic design and fabrication techniques.

We are hoping you will regularly read this blog and become part of our growth journey, sharing our content, giving us subject and issues to write about. View this as a the beginning of the plastic fabrication community.

We are excited about our future!